PTFE Heat Shrinkable Sleeving

1

/

of

1

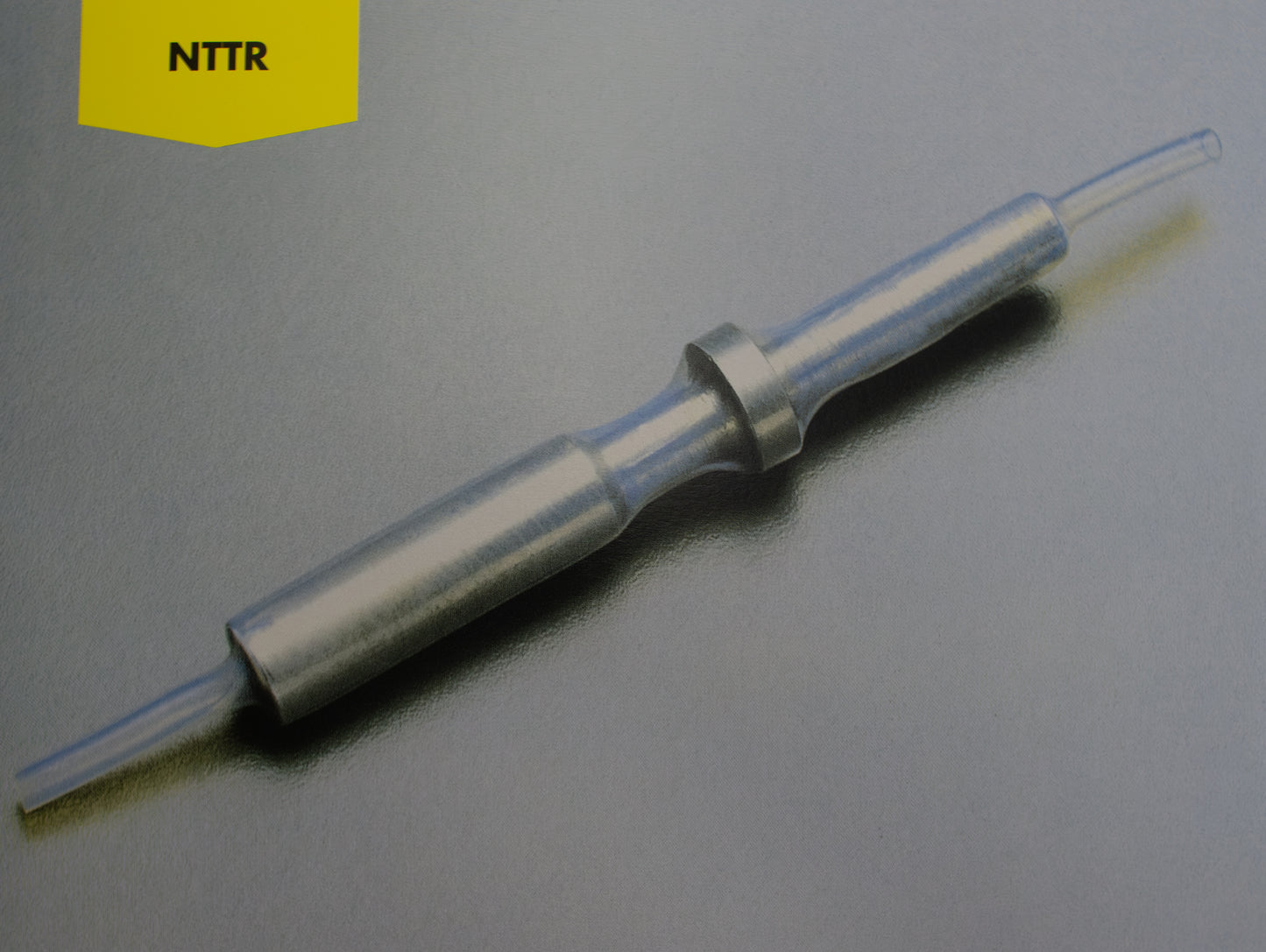

NTTR is made from PTFE. The PTFE heat shrinkable sleeving will operate at very high continuous temperatures of up to 260%C. It is resistant to chemical attack in the most hostile of environments, is non burning and features a wide ranging 4:1 shrink ratio.

Available as a translucent sleeving in a range of sizes up to nearly 32mm diameter, NTTR exhibits an extremely low coefficient of friction making it ideal for applications such as bearing shafts as well as high temperature applications such as hydraulic hose fittings and coupling covers.

Physical Properties

| Shrink ratio | 4:1 |

| Material | Polytetraflouroethylene |

| Flexibility | Semi flexible |

| Colours | Translucent |

| Tensile strength | 17.5N/mm” |

| Ultimate elongation | 200% min |

| Relative density | 2.2 max. |

| Longitudinal change | 20% max. |

Thermal Properties

| Operating temperature range | -65°C to + 260°C |

| Shrinkage temperature | >350°C |

| Storage stability | Excellent |

Electrical Properties

| ielectric strength | 40KV/mm |

| Volume resistivity | 10Õ8ohm.cm. |

Chemical Properties

| Water absorption | 0.1% (24h at 25°C) |

| Corrosion | Non-corrosive |

| Flammability | Non-burning |

| RODUCT CODE REF. | Internal Diameter (mm) | Nominal wall thickness (mm) after heating (full recovery) | Standard reel size (mtrs) | |

|---|---|---|---|---|

| Expanded As supplied min. | Recovered after heating max. | |||

| NTTR20 | 1.9 | 0.7 | 0.23 | 1.2 or 30 |

| NTTR32 | 3.1 | 1 | 0.25 | 1.2 or 30 |

| NTTR48 | 4.7 | 1.3 | 0.28 | 1.2 or 30 |

| NTTR64 | 6.3 | 1.6 | 0.3 | 1.2 or 30 |

| NTTR95 | 9.5 | 2.5 | 0.3 | 1.2 |

| NTTR127 | 12.7 | 3.7 | 0.38 | 1.2 |

| NTTR158 | 15.8 | 4.6 | 0.38 | 1.2 |

| NTTR190 | 19 | 5.7 | 0.38 | 1.2 |

| NTTR254 | 25.4 | 7.1 | 0.38 | 1.2 |

| NTTR320 | 31.7 | 8.9 | 0.38 | 1.2 |