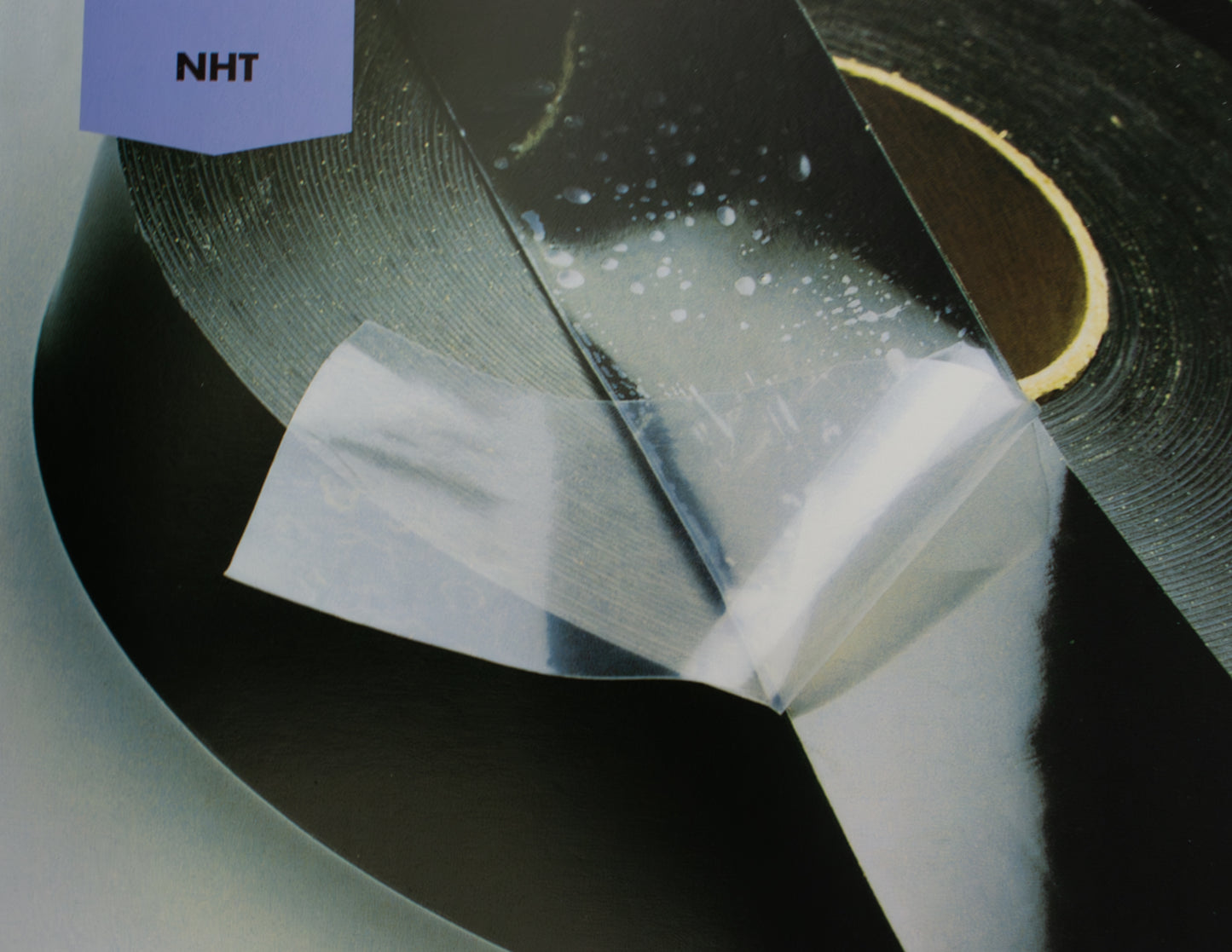

Heat Shrink Tape

NHT is a heatshrinkable cross-linked polyolefin tape coated on one side with a hot melt sealant. It has innumerable applications and will provide a flexible and durable environmental seal, useful as a temporary low cost repair to PVE or polyolefin jacketed cables where immediate replacement is either inconvenient or expensive.

Physical Properties

| Shrink ratio | 1.1:1 |

| Material | Adhesive lined polyolefin |

| Flexibility | Very flexible |

| Colours | Black |

| Tensile strength | 17.5N/mm” |

| Ultimate elongation | 600% min |

| Adhesion peel strength | 2,2kg/cm (to galvanised steel) |

| Minimum longitudinal shrinkage |

10% |

| Thickness of backing | 0.45mm |

| Total thickness | 1.05mm |

Thermal Properties

| Operating temperature range | -18°C to + 55°C |

| Shrinkage temperature | >135°C |

Electrical Properties

| Dielectric strength | 26KV/mm |

Chemical Properties

| Flammability | Not flame retarded |

| PRODUCT CODE REF | Nominal Tape Width (mm). | Nominal Roll Length (mtrs). |

|---|---|---|

| NHT37 | 37 | 25 |

| NHT50 | 50 | 25 |

| NHT75 | 75 | 25 |

| NHT100 | 100 | 25 |

Method of application

The appropriate length of tape is cut from a roll, wrapped snugly around the substrate, ensuring a continued overlap around the circumference equivalent approximately to the width of the tape. eg. 50mm wide tape overlaps by a further 50mm after the join. It is useful to hold the loose end in place with a small holding tab, then removing the thin protective film, before heat is applied to the tape.

As sufficient heat is applied, from the holding tab area first, the tape will be seen to shrink tightly, forcing the melted adhesive to flow into surface contours and to the edges of the tape. Allow ample time for cooling before handling. If the tape should need to be removed, apply heat until the adhesive melts (approx. 120¡C).