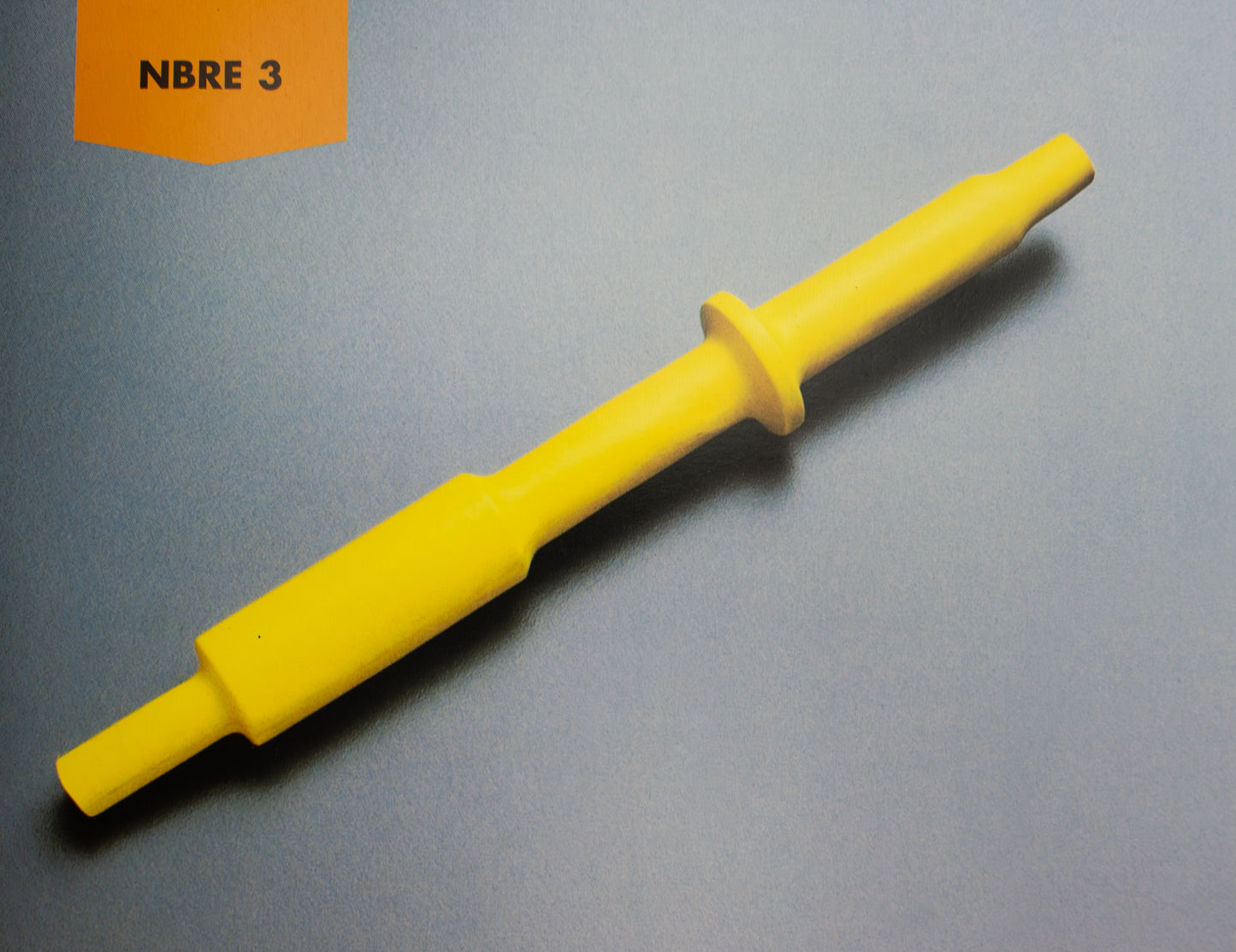

3:1 Thin Walled Polyolefin Sleeving

1

/

of

1

The advantages of a premium grade thin wall polyolefin combined with the versatility of a good 3:1 shrink ratio. Also available in a range of sizes up to 39mm diameter, NBRE 3 complies with MIL-1-23053/5 Class 1 and 2*, DEF>STAN 59-97 type 2b*, UL 224*, CSA* specifications.

The NBRE 3 shrink ratio enables fewer sizes to be stocked for a wider range of applications. The added advantage of NBRE 3 availability in a range of colours, makes this versatile tubing ideal for strain relief, protection of terminals and both coding and identification.

Physical Properties

| Shrink ratio | 3:1 |

| Material | Cross-linked polyolefin |

| Flexibility | Semi flexible |

| Colours | Standard: Black, Red, Blue, Yellow, White and Clear |

| Tensile strength | 10.4N/mm” |

| Ultimate elongation | 200% |

| Relative density | 1.3 max. |

| Longitudinal change | 10% max. |

Thermal Properties

| Operating temperature range | -55°C to + 135°C |

| Shrinkage temperature | >120°C |

| Storage stability | Very good |

Electrical Properties

| Dielectric strength | 20KV/mm |

| Volume resistivity | 10Õ4ohm.cm. |

Chemical Properties

| Water absorption | 0.4% (24h at 25°C) |

| Corrosion | Non-corrosive |

| Flammability | Self-extinguishing* |

- Does not apply to clear variant

| PRODUCT CODE REF. | Internal Diameter (mm) | Nominal wall thickness (mm) after heating (full recovery) | Standard reel size (mtrs) | |

|---|---|---|---|---|

| Expanded As supplied min. | Recovered after heating max. | |||

| NBRE3/15 | 1.5 | 0.5 | 0.45 | 300 |

| NBRE3/30 | 3 | 1 | 0.55 | 150 |

| NBRE3/60 | 6 | 2 | 0.65 | 60 or 75 |

| NBRE3/90 | 9 | 3 | 0.75 | 60 or 75 |

| NBRE3/120 | 12 | 4 | 0.75 | 60 or 75 |

| NBRE3/180 | 18 | 6 | 0.85 | 60 or 75 |

| NBRE3/240 | 24 | 8 | 1 | 30 |

| NBRE3/390 | 39 | 13 | 1.15 | 30 |

| NBRE190 | 19 | 9.5 | 0.76 | 75 |

| NBRE254 | 25.4 | 12.7 | 0.89 | 30 |

| NBRE380 | 38 | 19 | 1.02 | 30 |

| NBRE510 | 51 | 25.4 | 1.14 | 30 |

| NBRE762 | 76 | 38 | 1.27 | 15 |

| NBRE1020 | 102 | 51 | 1.4 | 15 |